iSAC Systems Inc. is a leader in the field of Internet-of-Things (IoT) and Artificial Intelligence (AI)-based Predictive Big Data Analytics.

For more than 10 years, iSAC Systems' solutions have revolutionize this field with its proprietary high-performance predictive algorithms,

flexible IoT & Predictive Big Data platform, and low power miniaturized IoT sensors and actuators.

The algorithms are based on iSAC Systems' proprietary methodology using seamless integration of artificial intelligence (AI), machine learning, and

model-based approaches. iSAC Systems' products on IoT and Predictive Big Data Analytics have been successfully deployed in different sectors in

Canada and worldwide.

iSAC Systems' new products are:

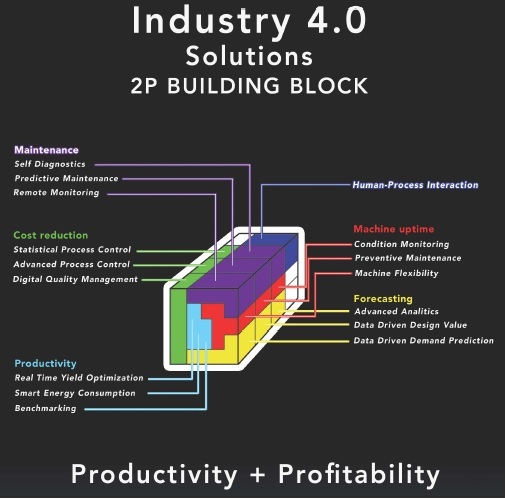

A suite of iSAC Smart Sensors or actuators along with proprietary algorithms empowers CNC machines to conduct tests themselves to enhance safety and reliability, without external test equipment or man-power. This feature leads to significant reduction in cost with limited technician accessibility.

iSAC Systems smart sensors monitors the condition and performance of CNC machines 24/7 and the AI and Machine learning based proprietary algorithms predict when maintenance is required for each machine with a goal to avoid both unnecessary scheduled maintenance and unplanned breakdowns.

iSAC Systems IoT platform provides real-time condition and performance of CNC machines to the customers remotely, via mobile apps/desktop computer apps. Alarms or anomalies information are immediately sent to the customers, at the time of their occurrences, via emails or phone text messages avoiding major delays.

iSAC Systems smart sensors measure key parameters of CNC machines in real-time and big data analytics employs statistical methods to analyze measured data and control quality during the manufacturing process in real-time.

iSAC Systems provides next generation Advanced process control (APC) that includes single-threaded run-to-run (R2R) process control, "supervised" fault detection and classification (FDC), improved data management and analysis capabilities through leveraging of big data architectures, and incorporation of prediction capabilities in solutions for improved manufacturing process quality and uptime with reduced cost.

iSAC Systems' solutions support digital transformation in quality management to enable customers to have major savings in costs and reduce the amount of manual errors.

With iSAC Systems' data analytics, a real time assessment of the yield of the machine is achieved. This feature can feed important information to production, to scheduling and to sales.

Respecting the environment, including compliance with government rulings on gas emissions, and profitability are the results of complete monitoring of the electrical system, from wiring and contactors to motors and drives. iSAC Systems' IoT sensors have a very short pay back time.

iSAC Systems' data acquisition and analytics on the machines provide benchmarks among themselves and other plants. These benchmarks are used to optimize the manufacturing process.

Essential to achieve higher yield and to improve profitability is the Machine Uptime. iSAC Systems' IoT platform provides constantly the necessary insight to the health of the machine.

iSAC Systems' data analytics allows the optimizing the timing of the preventive maintenance according solely to necessity without stopping the manufacturing operations.

Using iSAC Systems IoT platform along with AI based data analytics, the machine working cycle is shortened and the machine is more available.

iSAC Systems’ Artificial Intelligence and Machine learning based data analytics provides forecast of parts requirements and failures of machines, tools, and machine subsystems (such as motors and drives) more than a month ahead or 6 months ahead in some cases.

iSAC Systems IoT solutions provide design and development of new products or operations based on real-world results.

iSAC Systems data anlytics solutions provide prediction of product demand more than 6 months ahead, based on real-world results.

Industry 4.0: What, Why and How

2PCube

Applications

Monitoring System for Aircraft Landing Gear

Monitoring System for Aircraft Landing Gear

Monitoring of Aircraft Wing Assembly

Fault Prognosis of Aircraft Engine

Graphical User Interface of Aircraft Engine Prognosis

Aircraft Engine Sensor Data

Aircraft Engine Prognosis Results Using iSAC's AI and Machine Learning Algorithms

Bogie Monitoring System

Bogie Monitoring System installed on Train

Bogie Monitoring System: iSAC Transmitter and Receiver

iSAC DAQ 300 Monitoring System

Grpahical User Interface on Tablet/iPAD

Temperature

Wireless Gas Sensor Networks

Graphical User Interface (Windows/Desktop)

Graphical User Interface (Web)

Tank Level Sensor Networks

Food Monitoring

Graphical User Interface (Web) for Wireless Temparture Sensor Networks

Food Monitoring: iSAC Transmitter and Receiver

iSAC ADAQ-R100 for Refrigerator

iSAC ADAQ-R100 Performance Results for Refrigerator

iSAC ADAQ-R100 Performance Results for Refrigerator

iSAC Systems 2pAI Cube: Results for CNC Machines

iSAC Systems 2pAI Cube: Fault Prediction Results for CNC Machines

iSAC DAQ300S: Sensors and Control for Puck Shooting Machine

iSAC SeedView: Wireless Sensor Networks

iSAC SeedView Sensor Mote (Transmitter)

iSAC SeedView Base Station

Features

Features